جميع المنتجات

-

ورقة المطاط الصناعي

-

ورقة المطاط سيليكون

-

ورقة المطاط درجة حرارة عالية

-

سيليكون أنبوب النتوء

-

سيليكون المطاط غسالات

-

البولي يوريثين اقتران

-

التعبئة Ptfe

-

الشريط طوقا Ptfe

-

بتف المغلفة الألياف الزجاجية النسيج

-

بتف شبكة

-

ptfe أنبوب

-

المطاط صدمة يتصاعد

-

ورقة من البلاستيك الملون

-

نايلون البلاستيك قضيب

-

ورق مقاوم للزيت

-

ورقة رغوة EPDM

-

حزام النقل PVC

-

ختم الزيت الصناعي

-

وسادة قطع PTFE

Kevlar Packing Coated with PTFE The Ultimate Sealing Material for High-Performance Applications in Industrial Equipmen

| مكان المنشأ | الصين |

|---|---|

| اسم العلامة التجارية | 3A Rubber |

| إصدار الشهادات | ISO9001 |

| رقم الموديل | 3A3005 |

| الحد الأدنى لكمية | 20 كجم |

| الأسعار | USD15.00 per kg |

| تفاصيل التغليف | التعبئة في لفات والكرتون والمنصات |

| وقت التسليم | 7-15days بعد استلام دفع المشتري |

| شروط الدفع | L/C ، D/A ، D/P ، T/T ، Western Union ، Moneygram |

| القدرة على العرض | 100000 كلغ / شهر |

اتصل بي للحصول على عينات مجانية وكوبونات

ال WhatsApp:0086 18588475571

(ويتشات): 0086 18588475571

سكايب: sales10@aixton.com

إذا كان لديك أي مخاوف، نحن نقدم المساعدة على الانترنت على مدار 24 ساعة.

xتفاصيل المنتج

| ضغط | 0 ~ 4MPA | المقاومة الكيميائية | ممتاز |

|---|---|---|---|

| قوة الشد | 25 ميجا باسكال | سطح | سلس |

| عرض | 3-100 مم | كيميائية | مقاومة |

| بناء | جديلة شعرية | التعبئة | كرتون ، صندوق خشبي |

| يضعط | 3-30MPa | صمود | جيد |

| مطبعة العمل | 2-20 ميجا باسكال | أنتجت | تصنيع CNC |

| شكل | التعبئة | عازل | ثابت |

| إبراز | Kevlar PTFE packing seal,PTFE coated industrial packing,high-performance Kevlar sealing material,PTFE coated industrial packing,high-performance Kevlar sealing material |

||

يمكنك تحديد المنتجات التي تحتاجها والتواصل معنا في لوحة الرسائل.

منتوج وصف

Kevlar Packing Coated with PTFE - The Ultimate Sealing Material for High-Performance Applications in Industrial Equipment

| Attribute | Value |

|---|---|

| Pressure | 0~4mpa |

| Chemical Resistance | Excellent |

| Tensile Strength | 25 MPa |

| Surface | smooth |

| Width | 3-100mm |

| Chemical | Resistance |

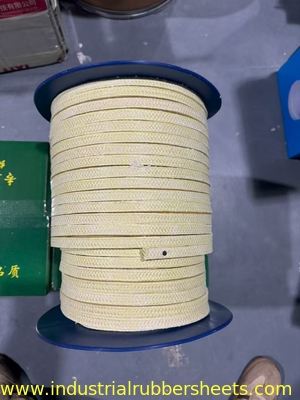

| Structure | lattice braid |

| Packing | Carton, Wooden Box |

| Press | 3-30Mpa |

| Resilience | Good |

| Working Press | 2-20Mpa |

| Produced | CNC machining |

| Shape | Packing |

| Dielectric | Constant |

Yellow Pure Kevlar Packing, Kevlar Braided Packing, Kevlar Packing Coated PTFE

Kevlar packing is a type of mechanical sealing material used to prevent leakage in pumps, valves, and other industrial equipment with rotating or reciprocating shafts. It is made from braided fibers of Kevlar® (an aramid fiber developed by DuPont), which is renowned for its exceptional strength, thermal stability, and resistance to abrasion. Unlike traditional packings like flax or graphite, Kevlar packing is a high-performance synthetic material designed to handle more demanding conditions.

Key Advantages and Properties

Kevlar packing offers a unique set of properties that make it superior to many traditional materials:

- Exceptional Strength and Toughness: Kevlar has a very high tensile strength (about 5 times stronger than steel on an equal-weight basis). This makes the packing highly resistant to extrusion, blowout, and wear, leading to a longer service life.

- Excellent Thermal Stability: It can operate continuously at temperatures up to 550°F (288°C) and can handle short-term spikes up to 800°F (427°C). This makes it suitable for hot water, steam, and other high-temperature fluids.

- High Chemical Resistance: It is resistant to a wide range of chemicals, including most solvents, oils, and acids (though it is not recommended for strong acids and strong alkalis).

- Low Coefficient of Friction: Kevlar fibers are inherently lubricious. This reduces friction and wear on the equipment's shaft or sleeve, which lowers power consumption and prevents damage to expensive components.

- Non-Abrasiveness: Unlike some reinforced materials, it is gentle on shafts and won't score or wear them down prematurely.

- Non-Asbestos & Environmentally Friendly: Kevlar packing was developed as a direct, superior replacement for hazardous asbestos-based packing.

Common Applications

Kevlar packing is versatile and used across numerous industries for sealing:

- Centrifugal and Rotary Pumps: Handling hot water, chemicals, slurries, and hydrocarbons.

- Valves: Especially in steam valves, gate valves, and control valves.

- Mixers and Agitators: Where abrasion resistance and strength are critical.

- Expansion Joints: For its flexibility and thermal properties.

- Industrial Equipment: In paper mills, chemical processing plants, power generation facilities, and marine applications.

Common Media Sealed: Hot water, steam, chemicals, acids, alkalis, oils, fuels, solvents, air, dyes, and many other aggressive fluids.

Types and Construction

Kevlar packing is rarely made from 100% Kevlar fibers. It is typically braided and combined with other materials to enhance its properties:

- Pure Kevlar Braid: Braided from 100% Kevlar yarn, often impregnated with a lubricant like PTFE (Teflon) or a proprietary grease. Excellent for general high-temperature service.

- Kevlar/PTFE Blend: Combines the strength of Kevlar with the incredible chemical resistance and low friction of PTFE. This is an extremely popular combination for a wide range of chemical services.

- Kevlar/Graphite Blend: Incorporates graphite for superior lubricity and higher temperature performance, ideal for demanding steam applications.

- Kevlar/Carbon Blend: Offers enhanced thermal conductivity and additional lubricity.

The packing can be square braided, braided over a core (jacketed), or interbraided with other materials.

Installation and Break-in Procedure

Proper installation is crucial for performance and longevity:

- Clean the Stuffing Box: Remove all old packing remnants and clean the shaft/sleeve.

- Measure and Cut: Precisely measure the shaft diameter and stuffing box bore to cut new rings. Always cut rings at a 45-degree angle (skive cut) and stagger the joints around the shaft.

- Install Rings: Carefully install each ring, using a tamping tool to seat each one firmly. Avoid twisting or distorting the rings.

- Adjust the Gland: After installation, hand-tighten the gland nuts.

- Break-in Period: This is critical. Start the equipment and gradually tighten the gland follower in small increments (e.g., 1/6 of a turn) every 10-20 minutes. The goal is to allow a few drops of leakage to cool and lubricate the packing. Never overtighten to stop all leakage immediately, as this will cause rapid, destructive overheating.

- Final Adjustment: Once the packing has settled and run-in (which can take several hours), adjust the gland so there is a minimal, controlled weep of fluid.

Limitations and Considerations

- Not for Strong Acids/Bases: While chemically resistant, prolonged exposure to strong mineral acids (e.g., sulfuric, nitric) and strong caustics (e.g., sodium hydroxide) can degrade the fibers.

- UV Degradation: Kevlar can degrade under prolonged exposure to ultraviolet light, but this is rarely an issue in an enclosed stuffing box.

- Cost: It is more expensive than traditional materials like graphite or flax, but its longer life and reduced downtime often result in a lower total cost of ownership.

Comparison Table: Kevlar vs. Other Common Packings

| Property | Kevlar Packing | Graphite Foil | PTFE (Teflon) | Cotton/Flax |

|---|---|---|---|---|

| Max Temp | 550°F (288°C) | 1000°F+ (538°C+) | 500°F (260°C) | 250°F (121°C) |

| Strength | Excellent | Poor | Good | Fair |

| Abrasion Resistance | Excellent | Fair | Good | Fair |

| Chemical Resistance | Very Good | Excellent | Excellent | Poor |

| Shaft Wear | Low | Can be high | Very Low | Moderate |

| Primary Use | Tough, abrasive, hot services | High-temp steam/air | Broad chemical service | Cold water, oils |

Summary

Kevlar packing is a high-performance, durable sealing solution ideal for applications that combine high pressure, high temperature, and abrasive media. Its unique blend of strength, thermal stability, and chemical resistance makes it a go-to choice for upgrading from traditional packings and solving difficult sealing challenges in demanding industrial environments. Always consult the manufacturer's specifications for your specific fluid, temperature, and pressure conditions.

المنتجات الموصى بها